1、產(chǎn)品按國(guó)家標(biāo)準(zhǔn)GBl2236設(shè)計(jì)制造��,結(jié)構(gòu)合理�����,密封可靠���,性能優(yōu)良。

2��、閥瓣���、閥座密封面采用鐵基合金或司太立(stellite)鈷基硬質(zhì)合金堆焊而成���,耐磨��、耐高溫�����、 耐腐蝕��、抗擦傷性能好�����、使用壽命長(zhǎng)�����。

3��、可采用各種配管法蘭標(biāo)準(zhǔn)及法蘭密封面型式,滿足各種工程需要及用戶要求�����。

4��、閥體材料品種齊全,填料�����、墊片可根據(jù)實(shí)際工況或用戶要求合理選配�����,能適用于各種壓力�、溫度及介質(zhì)工況。

5����、閥瓣轉(zhuǎn)繞閥座外的銷軸旋轉(zhuǎn),減少關(guān)閉時(shí)發(fā)生猛烈沖擊���。

6�����、銷軸與閥瓣連接采用內(nèi)裝式結(jié)構(gòu)����,不存在外泄漏點(diǎn)�����,使用更可靠。

電站旋啟式止回閥相關(guān)型號(hào):

|

配管法蘭

Pipe arrangement flange |

公稱壓力PN(MPa)

Nominal pressure |

法蘭密封面

Flange’s sealing face |

產(chǎn)品型號(hào)

|

|

JB/T74

GBgll3

GB20592~ 20635 |

1.6 |

凸面

Convex face |

H64H-16C |

H64W-16R |

H64W-16P |

H64y-16l |

|

2.5 |

H64H-25 |

H64W-25R |

H64W-25P |

H64y-25l |

|

4.O |

凹凸面

Concave-convex face |

H64H-40 |

H64W-40R |

H64W-40P |

H64y-40l |

|

6.4 |

H64H-64 |

H64W-64R |

H64W-64P |

H64y-64l |

|

10.O |

H64H-1OO |

H64W-100R |

H64W-100P |

H64y-100l |

|

16.O |

H64H-160 |

H64W-160R |

H64W-160P |

H64y-160l |

|

25.O |

H64H-250 |

H64W-250R |

H64W-250P |

H64y-250l |

電站旋啟式止回閥標(biāo)準(zhǔn)及規(guī)范:

|

設(shè)計(jì)與制造

Design and manufacture |

結(jié)構(gòu)長(zhǎng)度

Face to face dimension |

壓力溫度等級(jí)

Grade of pressure-temperature |

連接法蘭

connecting flange |

試驗(yàn)與檢驗(yàn)

Test and inspection |

|

GBl2236 |

GBl22221 |

GB9131 JB/T74 HG20604 |

JB/T74

GB9131

HG20592~20635 |

GBl3927

JB/T9092-1999 |

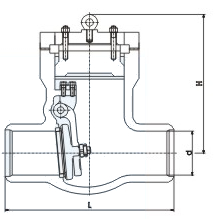

電站旋啟式止回閥結(jié)構(gòu)圖:

電站旋啟式止回閥主要連接尺寸:

|

公稱壓力PN(MPa)

Nominal

pressure |

公稱通徑

DN(mm)

Nominal

diameter |

外形尺寸和連接尺寸/mm Dimensions

|

重量/kg

Weight |

|

L |

D |

D1 |

D2 |

b-f |

Z-ød |

D3 |

H |

|

1.6 |

50 |

230 |

160 |

1 25 |

1 00 |

1 6-2 |

4-1 8 |

1 85 |

1 60 |

22 |

|

65 |

290 |

180 |

1 46 |

1 20 |

1 8-3 |

4-1 8 |

21 5 |

1 77 |

26 |

|

80 |

31 O |

195 |

1 60 |

1 35 |

20-3 |

8-1 8 |

235 |

1 87 |

33 |

|

1 00 |

350 |

215 |

1 80 |

1 55 |

20-3 |

8-1 8 |

255 |

202 |

39 |

|

1 25 |

400 |

245 |

21 O |

1 85 |

22-3 |

8-1 8 |

285 |

227 |

57 |

|

1 50

|

480

|

280

|

240

|

21 O

|

24-3

|

8-23

|

330

|

263

|

80

|

|

200 |

550 |

335 |

295 |

265 |

26-3 |

12-23 |

385 |

293 |

95 |

|

250 |

650 |

405 |

355 |

320 |

30-3 |

12-25 |

455 |

330 |

1 75 |

|

300 |

750 |

460 |

41 O |

375 |

30-4 |

12-25 |

51 5 |

382 |

260 |

|

350 |

850 |

520 |

470 |

435 |

34-4 |

16-25 |

545 |

430 |

360 |

|

400 |

950 |

580 |

525 |

485 |

36-4 |

16-30 |

600 |

480 |

496 |

|

500 |

1 1 50 |

705 |

650 |

608 |

44-4 |

20-34 |

730 |

560 |

588 |

|

2.5 |

50 |

230 |

1 60 |

1 25 |

1 00 |

20-3 |

4-1 8 |

1 85 |

1 77 |

22 |

|

65 |

290 |

1 80 |

1 45 |

1 20 |

22-3 |

8-1 8 |

21 5 |

1 92 |

30 |

|

80 |

31 O |

1 95 |

1 60 |

1 35 |

22-3 |

8-1 8 |

235 |

1 92 |

35 |

|

1 00 |

350 |

230 |

1 90 |

1 60 |

24-3 |

8-23 |

260 |

21 7 |

52 |

|

1 25 |

400 |

245 |

220 |

1 88 |

28-3 |

8-25 |

296 |

250 |

73 |

|

1 50

|

480

|

300

|

300

|

21 8

|

30-3

|

8-25

|

330

|

270

|

1 03

|

|

200 |

550 |

360 |

350 |

276 |

34-3 |

12-25 |

380 |

350 |

1 35 |

|

250 |

650 |

425 |

370 |

332 |

36-3 |

12-30 |

430 |

41 O |

1 96 |

|

300 |

750 |

485 |

430 |

390 |

40-4 |

16-30 |

490 |

430 |

285 |

|

350 |

850 |

550 |

490 |

448 |

44-4 |

16-34 |

545 |

450 |

388 |

|

400 |

950 |

61 O |

550 |

505 |

48-4 |

16-34 |

600 |

560 |

496 |

|

500 |

1 1 50 |

730 |

660 |

61 0 |

52-4 |

20-41 |

730 |

61 8 |

641 |

|

公稱壓力

PN(MPa)

Nominal

Dressure |

全稱通徑

DN(mm)

Nominal

diameter |

外形尺寸和連接尺7/mm Main external and connecting dimensions |

重量/kg Weight |

|

L |

D |

D1 |

D2 |

D6 |

b-f |

f2 |

Z-d |

D3 |

H |

|

4.O |

50 |

230 |

160 |

125 |

100 |

88 |

20-3 |

4 |

4-18 |

185 |

177 |

22 |

|

65 |

290 |

180 |

145 |

120 |

11O |

22-3 |

4 |

8-18 |

21O |

192 |

30 |

|

80 |

31O |

195 |

160 |

135 |

121 |

22-3 |

4 |

8-18 |

235 |

192 |

34 |

|

1OO |

350 |

230 |

190 |

160 |

150 |

24-3 |

4.5 |

8-23 |

260 |

217 |

52 |

|

125 |

400 |

270 |

220 |

188 |

176 |

28-3 |

4.5 |

8-25 |

295 |

259 |

73 |

|

150 |

480 |

300 |

250 |

218 |

204 |

30-3 |

4.5 |

8-25 |

330 |

270 |

103 |

|

200 |

550 |

375 |

320 |

282 |

260 |

38-3 |

4.5 |

12-30 |

450 |

340 |

212 |

|

250 |

650 |

445 |

385 |

345 |

313 |

42-3 |

4.5 |

12-34 |

445 |

401 |

297 |

|

300 |

750 |

510 |

450 |

408 |

364 |

46-4 |

4.5 |

16-34 |

545 |

423 |

362 |

|

350 |

850 |

570 |

51O |

465 |

422 |

52-4 |

5 |

16-34 |

570 |

460 |

450 |

|

400 |

g50 |

655 |

585 |

535 |

474 |

58-4 |

5 |

16-41 |

625 |

490 |

585 |

|

500 |

1150 |

755 |

670 |

612 |

576 |

62-4 |

5 |

20-48 |

730 |

618 |

641 |

|

6.4 |

50 |

300 |

175 |

125 |

105 |

88 |

26-3 |

4 |

4-23 |

21O |

192 |

30 |

|

65 |

340 |

200 |

160 |

130 |

11O |

28-3 |

4 |

8-23 |

235 |

207 |

41 |

|

80 |

380 |

210 |

170 |

140 |

121 |

30-3 |

4 |

8-23 |

235 |

207 |

48 |

|

1OO |

430 |

250 |

200 |

168 |

150 |

32-3 |

4.5 |

8-25 |

270 |

235 |

72 |

|

125 |

500 |

295 |

240 |

202 |

170 |

36-3 |

4.5 |

8-30 |

315 |

265 |

108 |

|

150 |

550 |

340 |

280 |

240 |

204 |

38-3 |

4.5 |

8-34 |

360 |

297 |

155 |

|

200 |

650 |

405 |

345 |

300 |

260 |

44-3 |

4.5 |

12-34 |

420 |

357 |

217 |

|

250 |

775 |

470 |

400 |

352 |

313 |

48-3 |

4.5 |

12-41 |

480 |

405 |

341 |

|

300 |

900 |

530 |

460 |

412 |

364 |

54-4 |

4.5 |

16-41 |

560 |

465 |

472 |

|

350 |

1025 |

595 |

525 |

475 |

422 |

60-4 |

5 |

16-41 |

615 |

514 |

627 |

|

400 |

1150 |

670 |

585 |

525 |

474 |

65-4 |

5 |

16-48 |

675 |

568 |

882 |

|

500 |

1400 |

800 |

705 |

640 |

576 |

70-4 |

5 |

20-54 |

735 |

620 |

1027 |

|

1O.O |

50 |

300 |

195 |

145 |

112 |

88 |

28-3 |

4 |

4-25 |

21O |

192 |

41 |

|

65 |

340 |

220 |

170 |

138 |

11O |

32-3 |

4 |

8-25 |

235 |

207 |

48 |

|

80 |

380 |

230 |

180 |

148 |

121 |

34-3 |

4 |

8-25 |

260 |

235 |

72 |

|

1OO |

430 |

265 |

21O |

172 |

150 |

38-3 |

4.5 |

8-30 |

295 |

265 |

108 |

|

125 |

500 |

310 |

250 |

210 |

175 |

42-3 |

4.5 |

8-34 |

335 |

313 |

130 |

|

150 |

550 |

350 |

290 |

250 |

204 |

46-3 |

4.5 |

12-34 |

425 |

360 |

217 |

|

200 |

650 |

430 |

312 |

312 |

260 |

54-3 |

4.5 |

12-41 |

450 |

420 |

341 |

|

250 |

775 |

500 |

382 |

382 |

313 |

60-3 |

4.5 |

12-41 |

535 |

480 |

472 |

|

公稱壓力

PN(MPa)

Norminal

pressure |

公稱通徑

DN(mm)

Nominal

diameter |

外形尺寸和連接尺寸/mm Dimensions |

重量/kg

Weight |

|

L |

D |

D1 |

D2 |

D6 |

b-f |

f2 |

Z-d |

H |

|

16.O |

50 |

300 |

215 |

165 |

132 |

88 |

36-3 |

4 |

8-25 |

251 |

49 |

|

65 |

340 |

245 |

1gO |

152 |

11O |

44-3 |

4 |

8-30 |

282 |

58 |

|

80 |

380 |

260 |

205 |

168 |

121 |

46-3 |

4 |

8-30 |

320 |

11O |

|

1OO |

430 |

300 |

240 |

200 |

150 |

48-3 |

4.5 |

8-34 |

356 |

162 |

|

125 |

500 |

355 |

285 |

238 |

176 |

60-3 |

4.5 |

8-41 |

393 |

214 |

|

150 |

550 |

390 |

318 |

270 |

204 |

66-3 |

4.5 |

12-41 |

430 |

267 |

|

200 |

650 |

480 |

400 |

345 |

260 |

78-3 |

4.5 |

12-48 |

470 |

318 |

|

250 |

750 |

580 |

485 |

425 |

313 |

88-3 |

4.5 |

12-54 |

514 |

370 |

|

25.O |

50 |

368 |

21O |

160 |

128 |

70 |

40-3 |

5 |

8-25 |

310 |

63 |

|

65 |

419 |

260 |

203 |

165 |

97 |

48-3 |

5 |

8-30 |

346 |

78 |

|

80 |

470 |

290 |

230 |

190 |

116 |

54-3 |

5 |

8-34 |

385 |

92 |

|

1OO |

546 |

360 |

2g2 |

245 |

138 |

66-3 |

6 |

8-41 |

406 |

168 |

|

125 |

673 |

385 |

318 |

270 |

170 |

76-3 |

6 |

12-41 |

534 |

220 |

|

150 |

705 |

440 |

360 |

305 |

190 |

82-3 |

6 |

12-45 |

560 |

270 |

|

200 |

832 |

535 |

440 |

380 |

245 |

92-3 |

6 |

12-51 |

318 |

320 |

|

250 |

991 |

670 |

572 |

508 |

319 |

110-3 |

6 |

16-55 |

673 |

390 |

一�����、①電站旋啟式止回閥產(chǎn)品名稱與型號(hào)②電站旋啟式止回閥口徑③電站旋啟式止回閥是否帶附件以便我們的為您正確選型����。

二、若已經(jīng)由設(shè)計(jì)單位選定正鋼閥門(mén)電站旋啟式止回閥型號(hào)����,請(qǐng)按電站旋啟式止回閥型號(hào)直接向我司銷售部訂購(gòu)。

三����、當(dāng)使用的場(chǎng)合非常重要或環(huán)境比較復(fù)雜時(shí),請(qǐng)您盡量提供設(shè)計(jì)圖紙和詳細(xì)參數(shù),由我們的正鋼閥門(mén)專家為您審核把關(guān)���。